This weekend we passed an important milestone, we moved Kinship back to Confederation Basin in downtown Kingston. It looks like we turned up way to early to the party but we are happy to be back.

Confederation Basin is 30 minutes less travel time from Ottawa and we don’t have to drive if we want to buy food or eat out, so life is a lot simpler. Cutting the cord at Loyalist Cove was hard, having skilled people around has been a big help, we were made very welcome and we were able to get a lot done. Before leaving we installed the radar and wind generator on the arch with help from Loyalist staff and we sent Kathleen up the mast to move the topping lift to the right side of spreaders before putting the boom back into place.

Kathleen up the mast.

Here I am wiring up the radar, sitting on the arch made this quite easy as everything was to hand.

Here I am wiring up the radar, sitting on the arch made this quite easy as everything was to hand.

After we took the ladder off the boat the last thing to was to remove the tether from the wind generator and test the systems. Everything on the arch is working well. we have to add the solar panels and the 2 sat phone systems and rig the dinghy lift but we are getting closer. Dave from Quinte Canvas has started work on the new bimini and enclosure, the frames are in place and he has made his patterns. Now it is a race between Dave finishing up and the mass invasion of Kingston may flies.

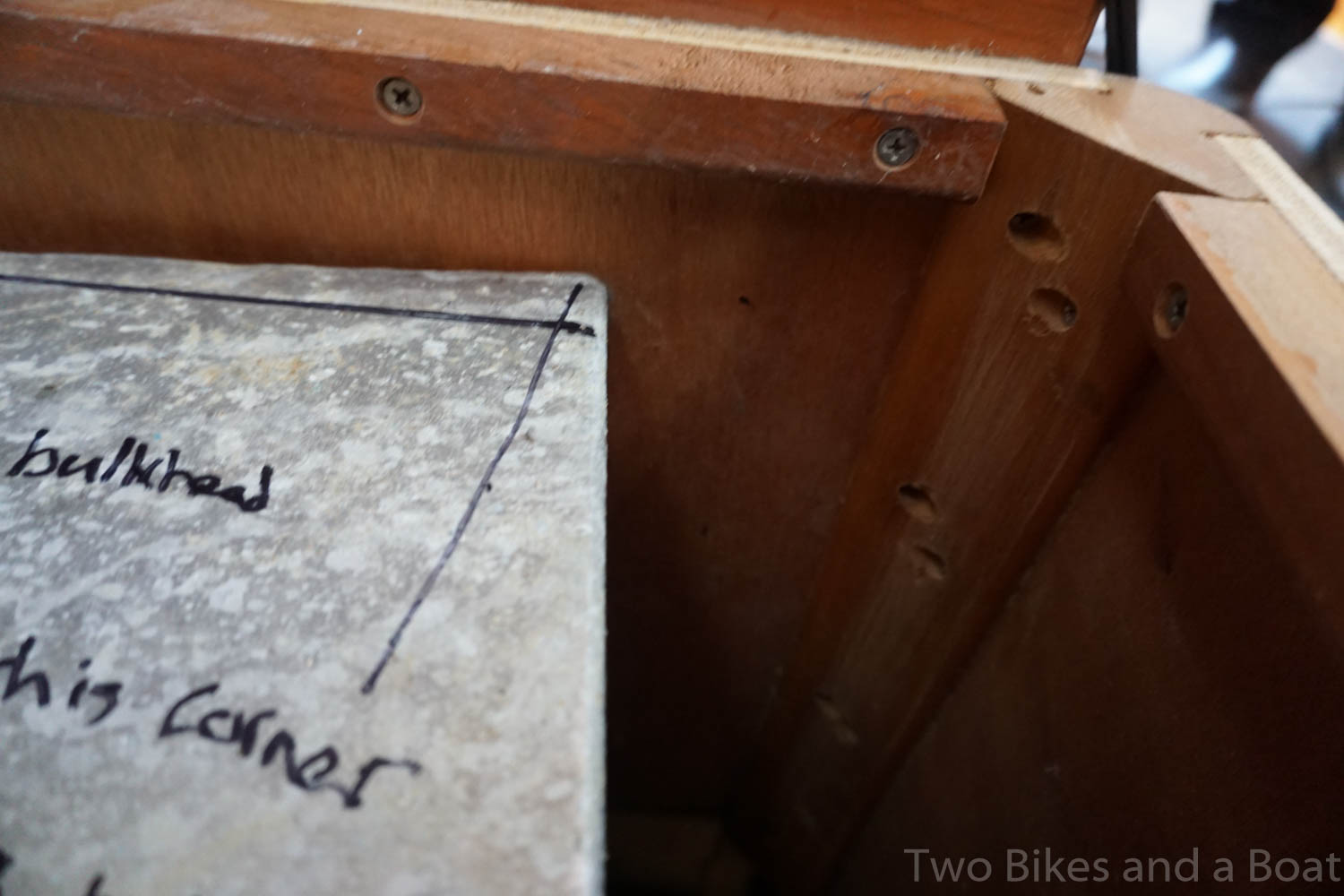

Kinship is cleaned up and looking great at least on the outside. On the inside we are still in the process of replacing the water tanks, the first one has been built, but more on that next time.